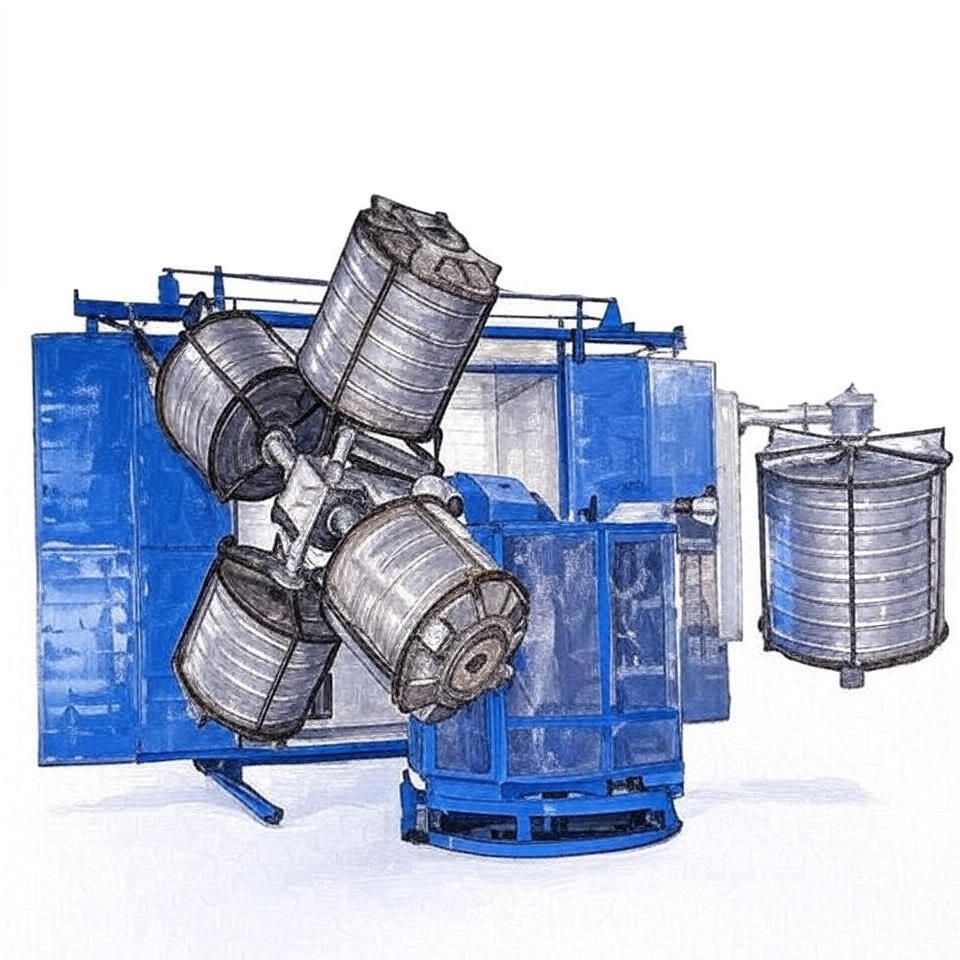

When most people think about grinding, they picture heat, friction, and heavy-duty machinery. But at Midwest Elastomers, we take a different approach — one that involves liquid nitrogen and ultra-low temperatures.

It’s called cryogenic grinding, and it’s a game changer in the world of rubber and plastic recycling.

How It Works

Cryogenic grinding uses liquid nitrogen to freeze materials like rubber or plastics until they’re brittle. Once frozen, those materials are much easier to grind into a fine, consistent powder. This technique is especially useful for materials that are soft, flexible, or heat-sensitive at room temperature.

By freezing them first, we avoid the clumping, melting, or degradation that can happen withtraditional grinding.

Why It’s Better

Here at Midwest Elastomers, we’ve been using cryogenic grinding for decades — and for good reason. It offers several important benefits:

• Better Quality Material: The process produces finer, cleaner, and more uniform particles. That’s important for manufacturers who need consistency in their end products.

• No Heat Damage: Because the material is frozen, it doesn’t break down or lose performance due to heat.

•

Cleaner Results: Less dust, less mess, and less wear and tear on our equipment — which means better results for our clients.

Who Uses It?

Cryogenic grinding is ideal for companies working with rubber, thermoplastics, or even specialty compounds. Whether you're in the automotive, construction, flooring, or consumer goods industry, the applications are wide-ranging.

At Midwest Elastomers, we partner with manufacturers who need high-quality ground material for everything from gasket production to molded parts and custom compounds.

Our Commitment to Quality

Our cryogenic grinding lines are just one part of what we offer at Midwest Elastomers. From precise particle sizing to custom material handling, we focus on quality, consistency, and sustainability in every project.

If you're looking for a dependable partner in rubber and plastic grinding — with decades of experience and a commitment to innovation — let's talk.

Interested in learning more about our cryogenic grinding services?

Fill out the form below, and our team will back to you to see how we can help with

your material processing needs.

Contact Us

MEI Blog