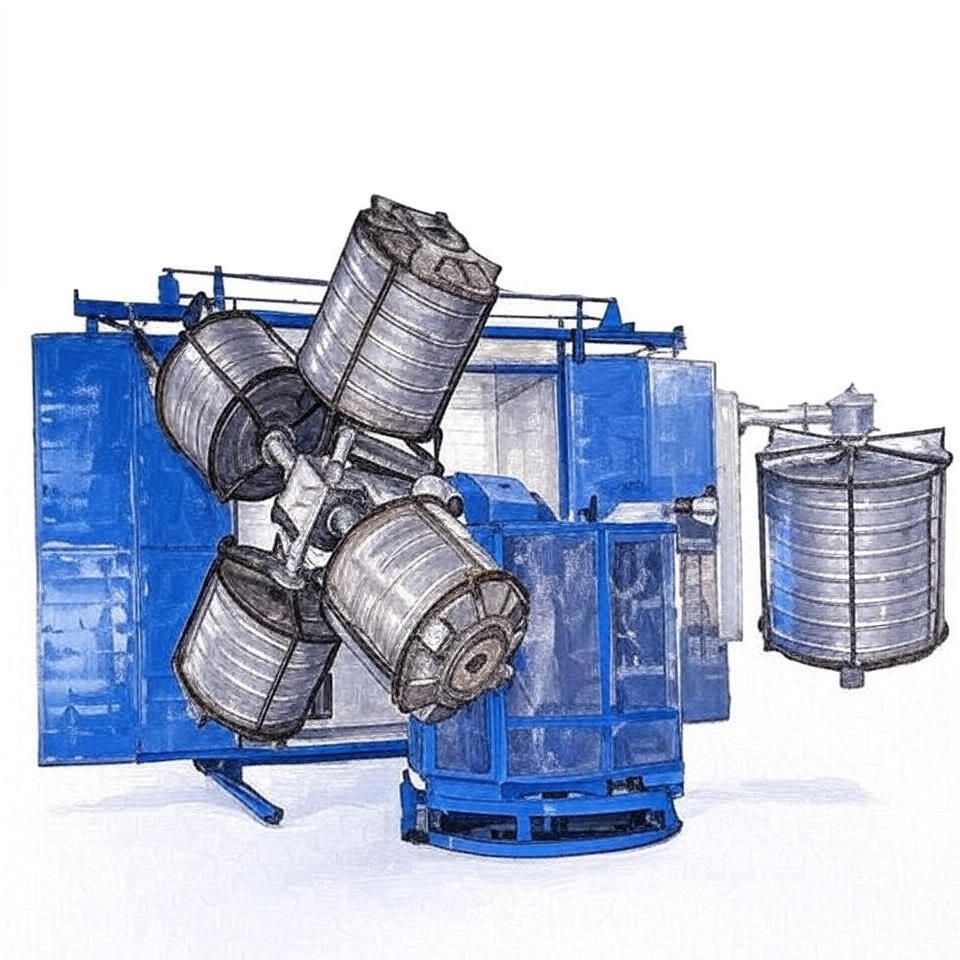

Turning pellet into powder might sound like a simple change—but in manufacturing, it’s a transformation that can drive serious results. When Nylon pellets are ground into a powder, the material behaves differently: it flows better, processes faster, and opens the door to higher-quality outcomes. Whether you're optimizing for precision or speed, powdered Nylon offers a powerful edge.

Why Powdered Nylon?

Nylon is a widely used thermoplastic thanks to its strength, chemical resistance, and versatility. However, transforming it from pellet to powder opens up new possibilities in performance and efficiency.

1. Enhanced Flowability

Powdered Nylon significantly improves material flow in manufacturing processes like rotational molding (roto-molding). A finer, more uniform powder ensures consistent layering and reduces the chance of clogs or irregular distribution—resulting in smoother, more reliable production runs.

2. Faster Dissolution Rates

One key advantage of grinding Nylon is its improved dissolution rate. Finer particles increase surface area, allowing materials to melt or dissolve more quickly. This can streamline production and improve the quality of the final product.

3. Energy Savings & Processing Efficiency

With faster melt rates and enhanced flow, powdered Nylon allows for quicker processing cycles—potentially leading to lower energy consumption and reduced operating costs. For manufacturers looking to optimize sustainability and profitability, this benefit alone is a game-changer.

4. Precision Mesh Sizes for Multiple Applications

MEI offers specialized grinding capabilities that produce Nylon powder in a range of mesh sizes:

- 20–35 mesh for rotational molding

- Up to 60 mesh for other demanding applications

Whether you're creating large molded components or high-performance parts, our custom mesh options provide the flexibility and quality you need.

5. Superior Moisture Control

Nylon is hygroscopic, meaning it readily absorbs moisture. Excess moisture can compromise material integrity during processing. MEI’s advanced cryogenic grinding process ensures moisture levels are tightly controlled—maintained between

0.05%–0.15%—to prevent defects and ensure product consistency.

Powdered Nylon offers more than just convenience — it delivers real advantages in speed, precision, and efficiency. With MEI’s advanced grinding expertise, you get material that’s ready to perform at the highest level. Let’s work together to power your next innovation.

Interested in grinding your Nylon pellets for better performance?

Contact MEI today to learn more about how our cryogenic grinding services can elevate your production process.

Contact Us

MEI Blog