Brake pads are critical for vehicle safety, converting kinetic energy into thermal energy through friction to slow or stop a vehicle. At Midwest Elastomers, we specialize in providing high-quality ground recycled rubber materials that enhance the performance of brake pad friction materials. This blog explores how ground rubber contributes to brake pad formulations, offering a balance of performance, sustainability, and cost-effectiveness.

The Role of Ground Rubber in Brake Pads

Ground rubber, derived from post-industrial rubber sources, is increasingly used in brake pad friction materials, particularly in non-asbestos organic (NAO) formulations. It serves multiple purposes:

- Noise and Vibration Dampening: Ground rubber acts as a lubricant and filler, reducing brake noise and vibrations, which enhances driver comfort. Its elasticity helps absorb vibrations, mitigating the squealing often associated with braking.

- Cost-Effectiveness: Incorporating ground rubber lowers production costs compared to other materials like Kevlar or ceramic fibers, making it an economical choice for manufacturers.

- Environmental Benefits: Using recycled ground rubber supports sustainability by repurposing waste materials, reducing landfill use, and aligning with eco-friendly manufacturing trends.

- Friction Modulation: Ground rubber contributes to a softer, smoother braking feel, ideal for daily driving conditions. It helps maintain a moderate coefficient of friction (typically 0.3–0.5), preventing wheel lockup while ensuring effective stopping power.

How Ground Rubber Enhances Brake Pad Performance

Brake pads rely on a complex blend of materials, including binders (e.g., phenolic resin), fibers, fillers, and friction modifiers. Ground rubber, often used as a filler or friction modifier, complements these components:

- Wear Characteristics: Organic brake pads with ground rubber wear faster than semi-metallic or ceramic pads, but they are gentler on brake rotors, extending rotor lifespan and reducing maintenance costs.

- Thermal Stability: While ground rubber has lower heat resistance compared to metallic or ceramic materials, it performs well in low-to-moderate temperature ranges (up to 250°C), making it suitable for standard passenger vehicles.

- Dust Reduction: Ground rubber in NAO pads produces less visible brake dust compared to semi-metallic pads, improving wheel aesthetics and reducing cleaning needs

Midwest Elastomers’ Contribution

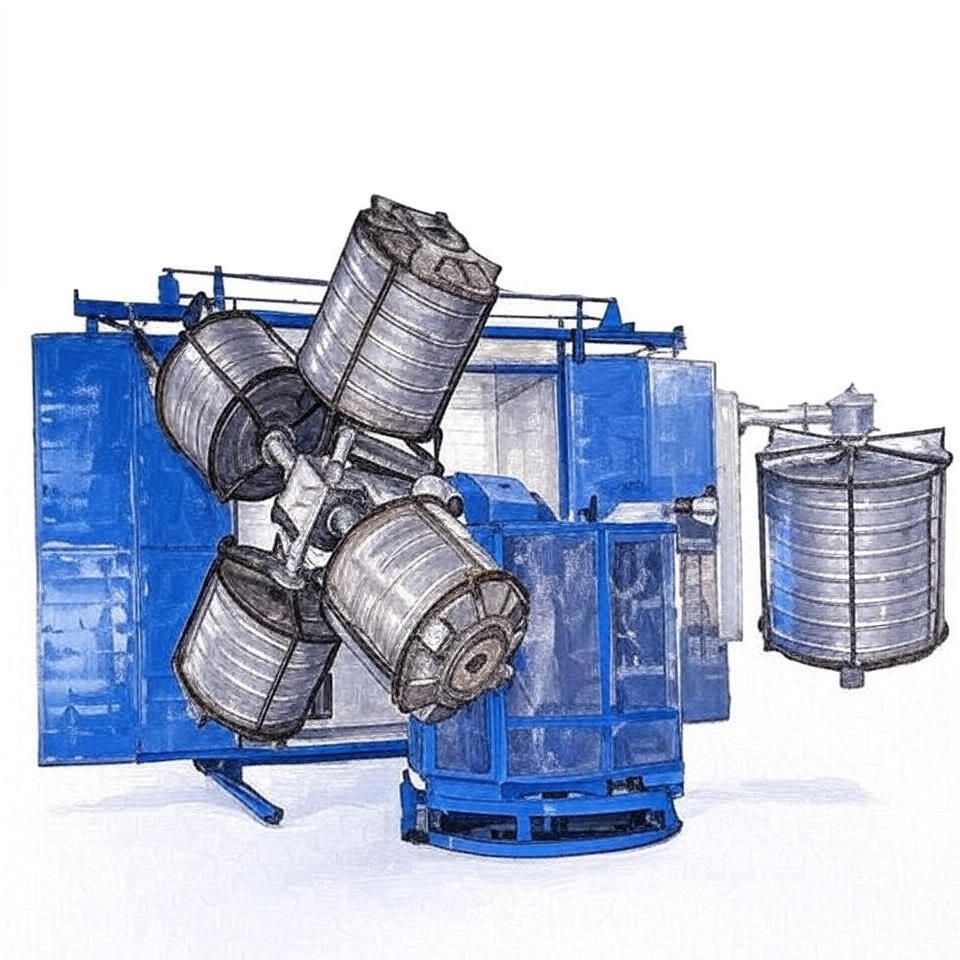

At Midwest Elastomers, we provide finely ground recycled rubber particles (down to 300 μm or smaller) tailored for brake pad manufacturing. Our advanced grinding processes ensure consistent particle size and quality, which are critical for achieving uniform friction properties and minimizing wear. By offering customizable ground rubber solutions, we help manufacturers optimize formulations for specific vehicle types and driving conditions.

Sustainability and Innovation

The use of ground recycled rubber aligns with the automotive industry’s shift toward eco-friendly materials. By incorporating recycled rubber, manufacturers can reduce the environmental impact of brake pad production while meeting regulatory requirements, such as those limiting copper content due to its impact on aquatic life. Additionally, research into natural fibers and waste materials highlights the potential for ground rubber to be part of innovative, sustainable friction material formulations.

Challenges and Considerations

While ground rubber offers numerous benefits, it has limitations:

- Performance Limits: Ground rubber is less suited for high-performance vehicles or extreme conditions due to its lower thermal stability and faster wear rate.

- Fade and Glazing: Under high temperatures, organic pads with ground rubber may experience fading (temporary loss of braking power) or glazing (hardening of the pad surface), reducing effectiveness.To address these, manufacturers often blend ground rubber with other materials, such as ceramic or metallic fibers, to balance performance and durability.

Ground rubber plays a vital role in modern brake pad friction materials, offering a cost-effective, sustainable, and performance-enhancing solution for NAO formulations. At Midwest Elastomers, we are committed to supporting the automotive industry with high-quality ground recycled rubber that meets stringent performance and environmental standards. By leveraging our expertise in material processing, we help manufacturers create brake pads that deliver safety, comfort, and sustainability.

Ready to elevate your brake pad formulations?

Connect with our team to learn how Midwest Elastomers’ ground rubber solutions can enhance performance, reduce costs, and support your sustainability goals.

Fill out the form below to start the conversation.

Contact Us

MEI Blog