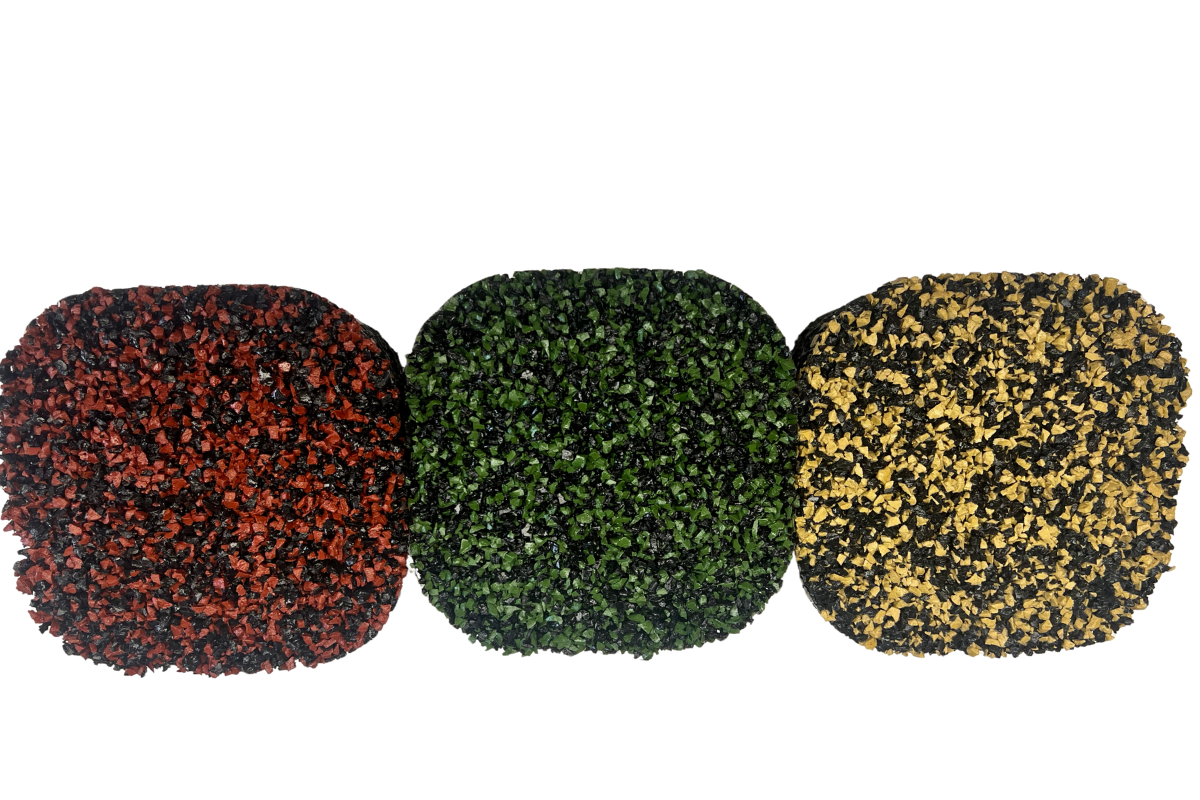

Tire buffings, also known as rubber buffings, are small rubber particles generated during the tire retreading process, typically sieved to specific mesh sizes (e.g., 4 to 10 mesh) for use in applications like safety surfacing for playgrounds and athletic fields. These materials, derived from recycled truck and semi tires, have long been valued for their durability, shock absorption, and cost-effectiveness in creating safe, cushioned surfaces.

However, the safety surface marketplace is evolving, with challenges such as inconsistent supply, environmental concerns, and the need for sustainable alternatives driving innovation. At Midwest Elastomers, as leaders in rubber processing, we are at the forefront of navigating these changes, and adapting to new materials & technologies to meet market demands.

The Role of Tire Buffings in Safety Surfacing

Tire buffings are a key component in several types of safety surfacing systems, as outlined by the Consumer Product Safety Commission (CPSC):

- Loose-Fill Rubber: Often referred to as rubber mulch, this consists of tire buffings or rubber nuggets used as loose-fill playground surfacing. It provides excellent impact attenuation but requires verification that it’s specifically designed for playground use, not landscaping.

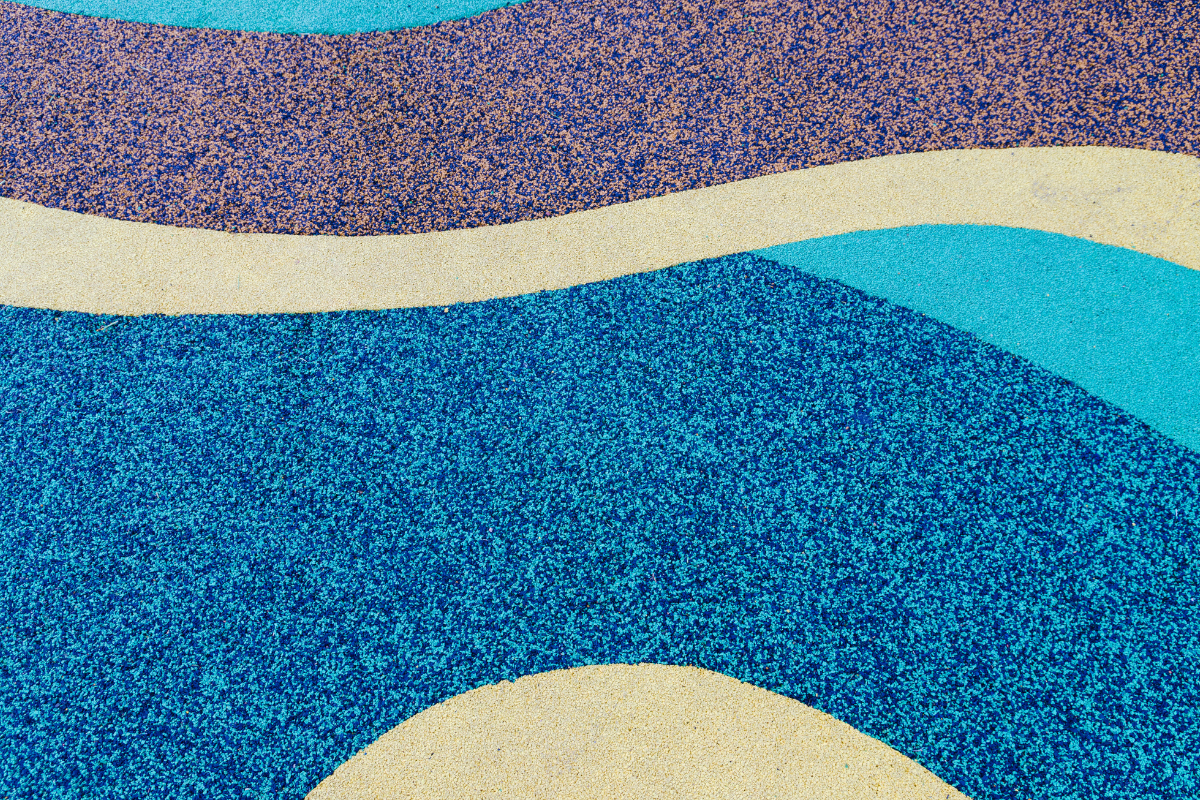

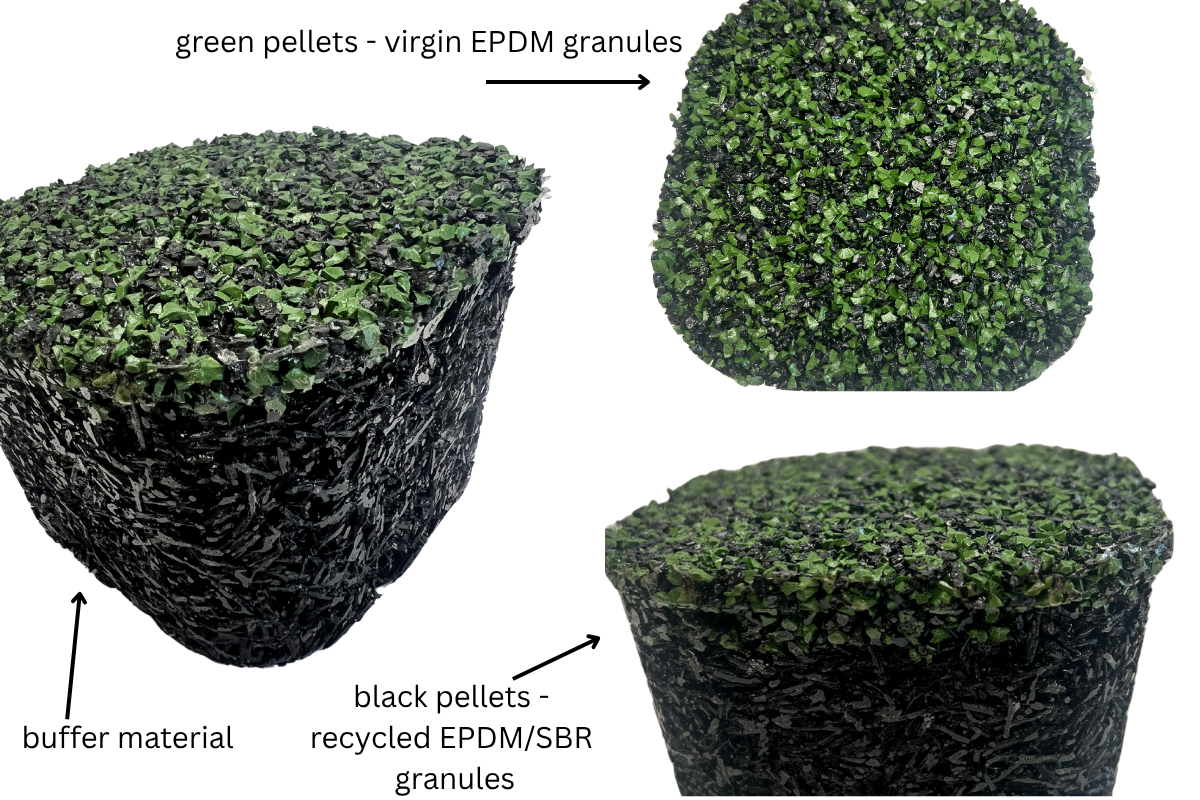

- Poured-in-Place (PIP) Systems: These combine tire buffings or crumb rubber with a polymer binder, poured on-site to create a seamless, cushioned surface with a wear-resistant top layer.

- Rubber Tiles: Factory-formed tiles or mats made from recycled tire rubber, including buffings, provide a unitary surface for playgrounds, offering consistent impact absorption.

The advantages of tire buffings include their low cost, availability from recycled tires, and ability to meet safety standards like ASTM F1292-13 for impact attenuation. However, supply chain disruptions, regional variations in tire recycling, and growing environmental concerns—such as potential chemical leaching from recycled tires—are prompting the industry to explore alternatives.

Challenges with Tire Buffings Supply

The tire recycling industry faces several hurdles that impact the availability of tire buffings:

- Volume and Consistency: In the U.S., approximately 240 million waste tires are generated annually, but only about 79% are recycled, with a significant portion used for tire-derived fuel (TDF) or landfilled, limiting the supply of buffings for safety surfacing (U.S. Tire Manufacturers Association).

- Environmental Concerns: Studies have raised concerns about chemicals like 6PPD-quinone, a tire rubber byproduct, prompting regulatory scrutiny and pushing manufacturers to seek safer alternatives (Climate Policy Watcher).

- Market Competition: Tire buffings compete with other recycled tire products, such as crumb rubber for asphalt or synthetic turf infill, reducing the amount available for safety surfaces.

These challenges have created a gap in the supply of tire buffings, forcing companies to innovate with alternative materials to meet the growing demand for safe, sustainable surfacing solutions.

Alternatives to Tire Buffings in the Safety Surface Marketplace

As the supply of tire buffings becomes less reliable, companies are turning to alternative materials to ensure performance, safety, and sustainability in the safety surface market. Below are some key alternatives being adopted:

1. Crumb Rubber from Non-Tire Sources

- Description: Crumb rubber, finer than buffings (typically <1/4" diameter), can be sourced from other recycled rubber products, such as industrial rubber mats or conveyor belts, rather than tires.

- Applications: Used in PIP systems and rubber tiles, crumb rubber offers similar impact attenuation and durability but avoids some tire-specific chemical concerns.

- Benefits: Reduces reliance on tire-derived materials, potentially lowers environmental risks, and maintains cost-effectiveness.

2. Polyurethane and Foam Composites

- Description: Polyurethane-based foams or composites, often combined with recycled materials, are used to create unitary surfaces like tiles or PIP systems, replacing tire buffings entirely.

- Applications: Ideal for playgrounds and indoor facilities where chemical exposure is a concern.

- Benefits: Offers consistent performance, customizable textures, and reduced environmental risks.

3. Eco-Friendly and Bio-Based Materials

- Description: Manufacturers are exploring sustainable materials like dandelion-derived rubber (Taraxagum) or recycled PET from plastic bottles to create rubber-like compounds for safety surfaces.

- Applications: These materials can be processed into granules or bound into PIP systems, offering similar cushioning properties.

- Benefits: Lowers carbon footprint, aligns with sustainability goals, and addresses chemical concerns.

4. Natural and Organic Fillers

- Description: Organic materials like cork or coconut fiber are being tested as loose-fill alternatives to rubber mulch, providing biodegradable options for safety surfaces.

- Applications: Loose-fill systems for playgrounds, particularly for toddler areas where loose rubber is less suitable.

- Benefits: Fully biodegradable, chemical-free, and environmentally friendly, though potentially less durable.

Midwest Elastomers’ Role in the Evolving Market

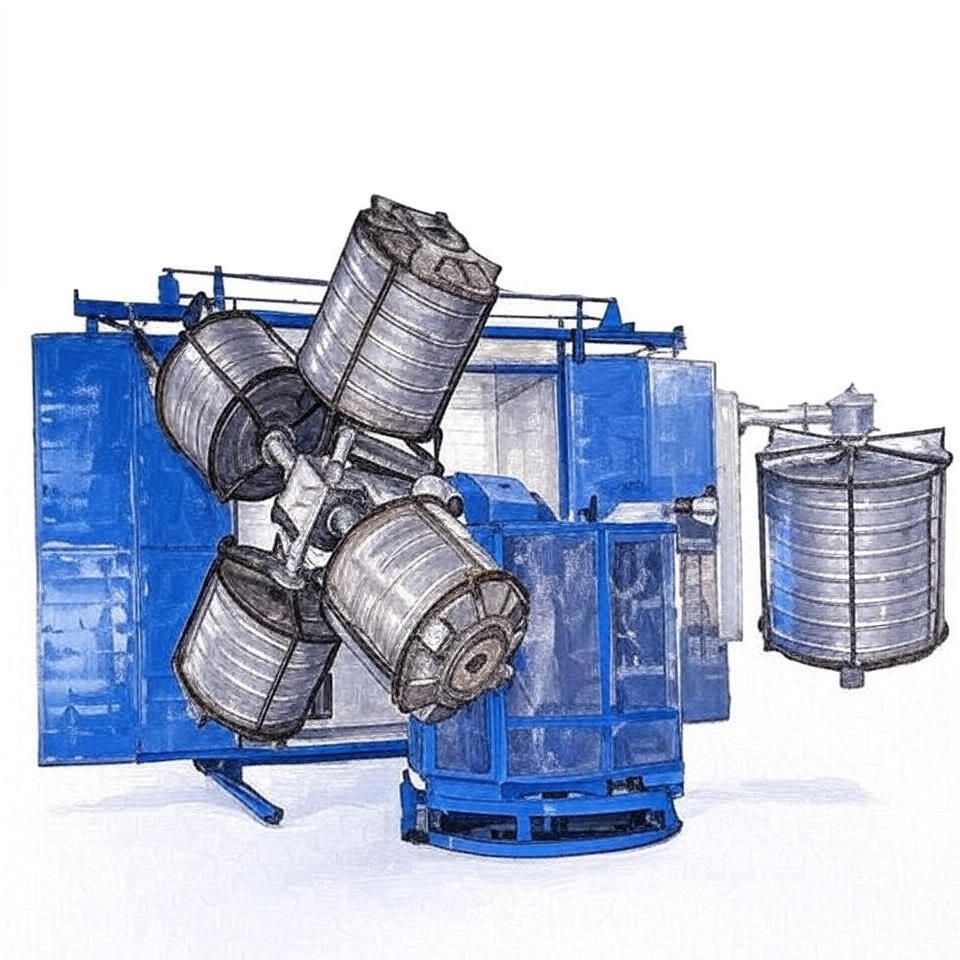

MEI specializes in processing recycled rubber, including tire buffings, into high-quality materials for safety surfacing and industrial applications. As the marketplace shifts, Midwest Elastomers is well-positioned to adapt by:

- Diversifying Material Sources: Incorporating non-tire crumb rubber and exploring bio-based alternatives to supplement tire buffings.

- Enhancing Processing Capabilities: Using advanced grinding and sieving technologies to produce consistent, high-quality granules from various rubber sources.

- Partnering with Innovators: Collaborating with companies like Continental or SDI to integrate sustainable materials like Taraxagum or recycled PET into their product lines.

- Meeting Safety Standards: Ensuring all materials, whether tire-derived or alternative, comply with ASTM F1292-13 and other safety regulations.

The Future of Safety Surfacing

The safety surface marketplace is moving toward greater sustainability and safety, driven by consumer demand and regulatory pressures. While tire buffings remain a cost-effective and reliable option, their limited supply and environmental concerns are pushing the industry toward alternatives like non-tire crumb rubber, synthetic turf infills, bio-based materials, polyurethane composites, and organic fillers. Midwest Elastomers is poised to lead this transition by leveraging its expertise in rubber processing and commitment to innovation.

In Conclusion

The tire buffing market is undergoing a transformation as companies address supply shortages and environmental challenges. By adopting alternatives like eco-friendly materials and non-tire rubber, the industry is ensuring safer, more sustainable surfaces for playgrounds and recreational spaces.

Looking Ahead

The safety surface market isn’t slowing down — and neither should your production. If you're searching for high-quality alternatives to tire buffings, we’re here to help.

Contact us today to learn more about our cryogenically ground rubber products and how

we can support your evolving material needs.

Contact Us

MEI Blog