Overconsumption is costing us more than we think.

Mindless production. Disposable systems. A constant race to scale—no matter the toll.

It’s not just hurting the planet. It’s weakening supply chains, overloading teams, and accelerating burnout across industries.

Mountains of waste. Strained supply chains. Teams expected to deliver more with fewer resources—while the planet absorbs the cost.

It’s a cycle that’s become business as usual.

But what if business as usual isn’t good enough anymore?

What if there’s a way to move faster and smarter—to boost performance without burning through people or the planet?

That’s the question we asked.

And in a quiet corner of Ohio, we found the answer.

Why It Matters in 2025—and Beyond

Here’s the reality:

- Over 300 million tons of plastic are produced every year

- Rubber waste alone contributes to 1.5 billion tons of landfill buildup

- These materials leach toxins into soil, water, and air for decades

The traditional approach? Send it to landfill, replace it with virgin material, repeat.

The impact? Sky-high costs, unpredictable supply chains, and irreversible damage to the planet

But rubber doesn’t have to rot.

It can be reused, reshaped, and reintegrated into sustainable supply chains.

Sustainability Isn’t a Side Effect—It’s the Strategy

We don’t make green goals after the fact. We include sustainability into every process, because we know: it’s not a cost—it’s a competitive edge.

Here’s how:

- Tolling services: Clients send us their waste; we grind and return it as reusable material

- Internal recycling: We reduce landfill output by reprocessing our own system’s scrap

- Material repurposing: Our products are designed for longer life cycles, reducing the need for replacements

In our Sports Surfacing Division, we transform recycled rubber into:

- Black EPDM & SBR granules

- Shock-absorbing rubber mulch (various colors available)

- Rubber buffings for safety surfaces

These surfaces outperform traditional materials—not just in resilience, but in environmental impact.

We don’t settle for “doing less harm.”

We aim to

do more good.

Productivity, Reimagined with Precision

At MEI, we’ve left the “more, faster, cheaper” mindset behind—because real progress demands smarter, cleaner, and more sustainable thinking.

Today’s world demands a better equation: efficient systems, minimal waste, and scalable impact.

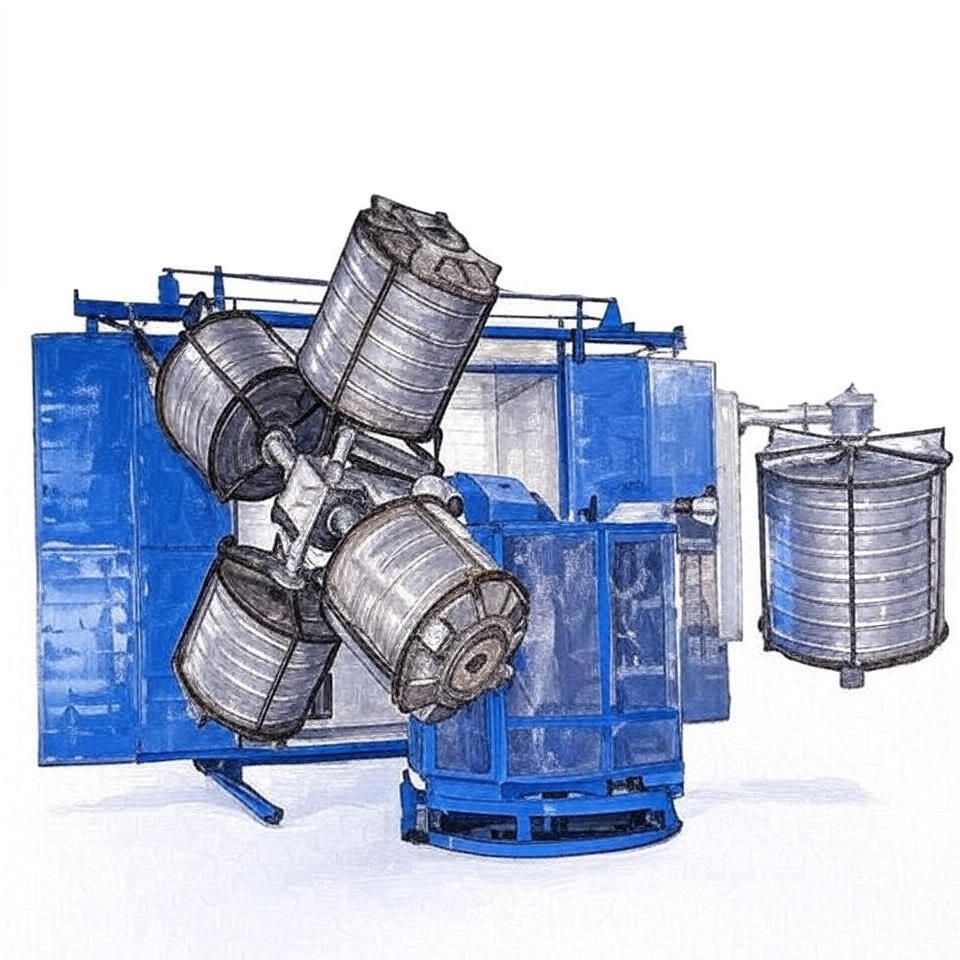

We’ve invested in advanced cryogenic and ambient grinding technologies—not just to process rubber, but to elevate it. Our methods aren’t just cleaner—they’re smarter.

Here’s how it works:

We process post-industrial rubber scrap, including:

- Butyl

- Natural Rubber

- Fluoroelastomer (FKM)

- SBR

- Nitrile

- Neoprene

- EPDM

We convert rubber into high-performance granules & powders—ranging from .5-1.5mm to 120 mesh—that help clients:

- Cut material costs

- Streamline production

- Improve output consistency

Backed by Science. Built for Scale.

Our cryogenic grinding process, powered by liquid nitrogen, yields finer, more uniform particles—using less energy than traditional methods. That translates into:

- Up to 30% productivity gains

- Reduced environmental impact

- ISO 9001:2015-certified quality

We don’t just chase efficiency. We design for it.

Our quality assurance isn’t a department—it’s a culture.

Every MEI team member is trained by our “Quality is the Cornerstone of MEI” policy.

This isn’t theory. It’s a proven model—and it’s built to grow with you.

"The greatest threat to our planet is the belief that someone else will save it."

— Robert Swan

The MEI Mindset: Progress with Purpose

Our difference isn’t just technical—it’s intentional.

We believe:

- Waste is potential

- Sustainability drives performance

- Everyone can be part of the solution

Whether you’re looking to reduce scrap, optimize materials, or build greener surfaces, we’re here to help you rethink what’s possible.

Let’s Make Productivity Green

The world is changing fast—and MEI is changing with it, without losing sight of what matters most.

Whether you need custom grinding, tolling services, or recycled rubber solutions, we’re ready to help you grow smarter, faster, and greener.

Let’s build a better future—together.

Let’s make productivity green.

Join the MEI movement—because thriving shouldn’t come at the planet’s expense.

Let’s Build Something Greener Together

Ready to turn waste into wins? Fill out the form and discover how MEI can help your business grow greener—without losing momentum.

Contact Us

MEI Blog