Plastics Grinding

Boaz Bowersock

Plastics Grinding Division Sales Manager

700 Industrial Drive

Wapakoneta, Ohio 45895

Direct Phone:

419-738-5425

Cell Phone:

419-996-8141

Fax:

419-738-4411

Email:

bbowersock@midwestelastomers.com

What We Offer

Midwest Elastomers specializes toll grinding plastic polymers, adhesives and ingredients to the polymer industry.

Our equipment consists of granulators, hammer mills, attrition mills, roll mills for cryogenics, ambient grinding, and classification.

We are experienced in producing acrylic polystyrene, polyester, ABS, PVC, TPE, TPU, polypropylene, nylon, EVA, adhesives and more. Particle distribution for cryogenic grinding 10 mesh to 80 mesh.

Paige Schreiber

Customer Service Representative

700 Industrial Drive

Wapakoneta, Ohio 45895

Direct Phone:

419-738-8844 x126

Trouble Free Customer Service

- ASTM certified product.

- ISO Quality registration, systems and certifications.

- In-spec; on-target.

- Contamination-free.

- Correct labeling, identification and packaging.

- Consistent quality material, shipment-to-shipment.

- On time, every time!

Request a Plastics Grinding Quote

Equipment

- Our equipment is sized for jobs from 1,000 pounds to truckloads.

- We can break down large sheets and can pre-process tough materials.

- Post Process heaters to control moisture on Cryogenic Processes

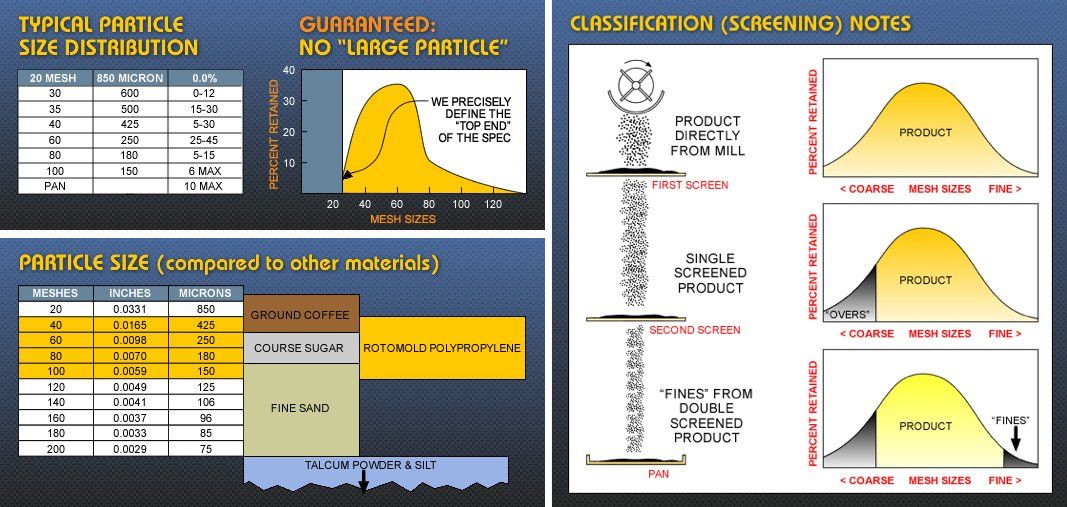

- Use of Sweco Classifiers for sharp cut of particle size distribution.

Cumberland Granulators

Mikropul Cryogenic Hammer Mills

Reduction Engineering Cryogenic Attrition Mill

American Pulverizer Hammer Mills

Gundlach Roll Mills

Applications

Color Chips

Solid surface color chips.

Powders

Powders for injection molding and extrusion.

Concentrated Powders

Powdered color concentrates.

Auto Interior

PVC, TPR. TPE grinding for auto interior skins.

Ground Polymers

Ground polymers for roto molding.

Recycled

Recycled polymer grinding and more.

R & D Trial Process

Tell us your needs:

- Material type, feed size

- Desired size, particle size distribution

- Volume requirements

Provide us:

- An MSDS Sheet

- A small sample (100 grams-1 pound)

We will:

- Evaluate MSDS data

- Conduct lab scale trial

- Contact you regarding a trial on production equipment

First trial:

- At least 50 pounds needed to determine grinding characteristics

- 500-1000 pound trial will give indication of production throughput and cost/pound

Ready to get started?

*General first trial setup fee is $1250 US Dollars.

Call us at 419.738.8844

Plastics Grinding Support

We provide consistent quality ground plastics products and quality service to our customers through our ISO 9001:2008 based quality system.

Ensuring quality for our customers with these available tests:

- Particle size distribution

- Moisture content

- Contamination

- Pourability

- Bulk density

* Particle size distribution is by RotTap® method.

We work with companies in development of specifications to ensure their ground plastics needs are satisfied. From the receipt of raw materials through the shipment of finished goods, MEI is dedicated to proving quality ground plastic products and services. Certificates of analysis on every order!

Nylon-6 Material Reduction

Wapakoneta, Ohio, August 24, 2018: MEI is proud to announce the addition of capabilities for size reduction of Nylon-6 materials. An investment in a state of the art climate controlled facility allows MEI to produce Nylon 6 material from 20 to 35 mesh for the rotational molding industry and finer sizes (60 mesh) for other markets. This addition in processing capabilities allows MEI to control the amount of moisture added to hydroscopic sensitive materials during the grinding and packaging phase. Finished goods moisture content is targeted from 0.05 – .15%.

For more information please feel free to contact:

Boaz Bowersock

Sales Manager, Plastics Grinding Division

700 Industrial Drive

Wapakoneta, OH 45895

Direct: (419) 738-5425

Cell: (419) 996-8141

Email:

bbowersock@midwestelastomers.com